Mulching Heads

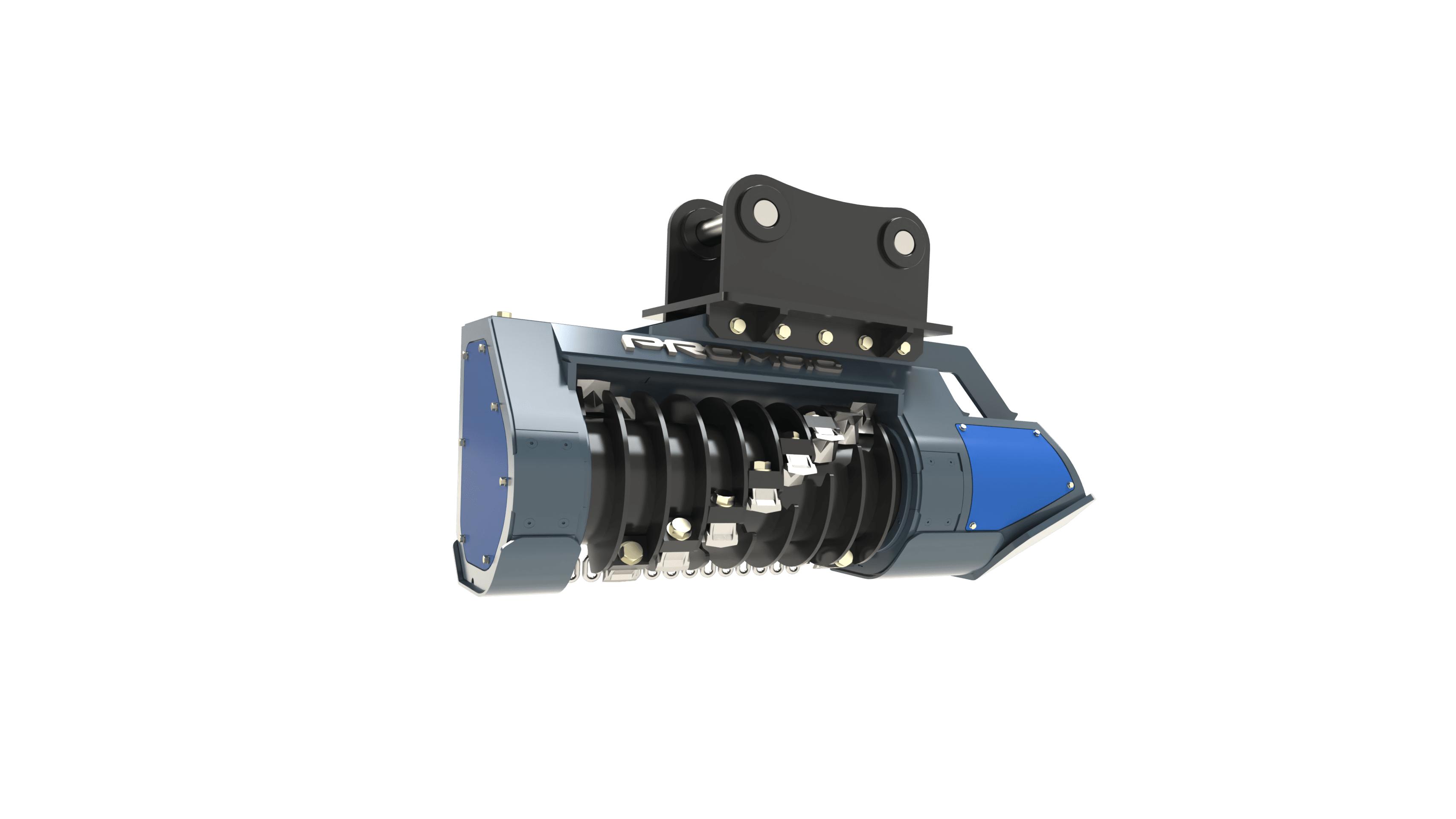

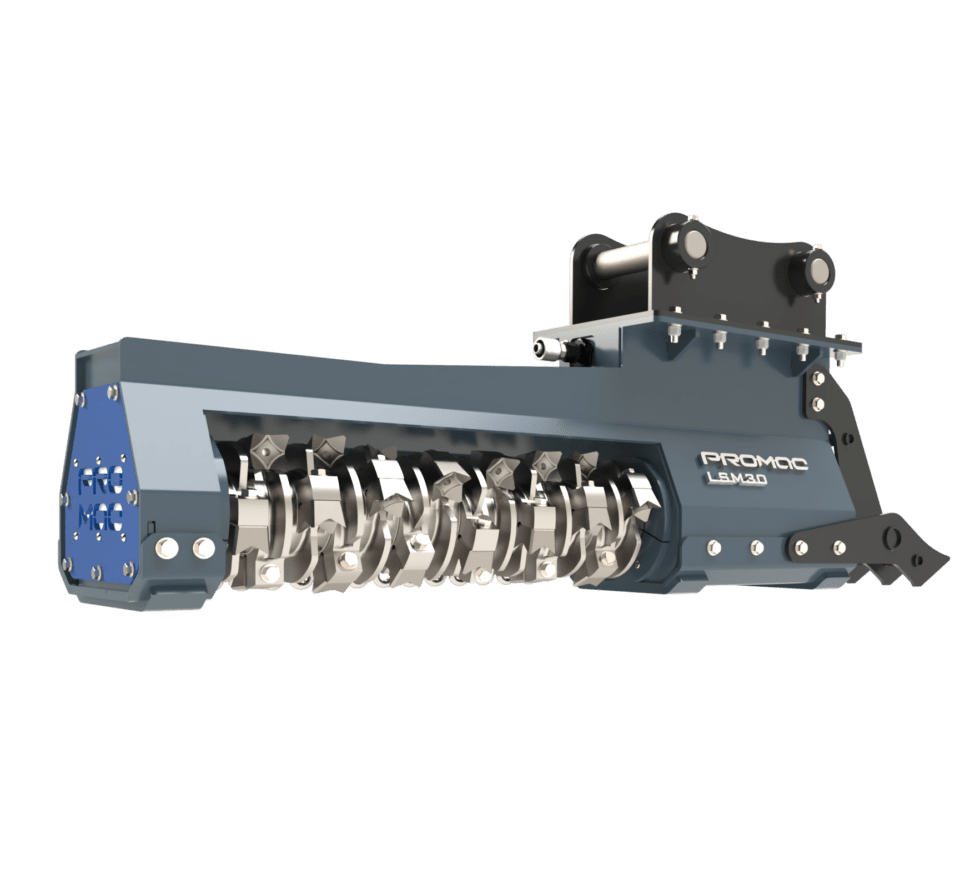

Promac LDM Series Excavator Mulcher

Mulching Heads

Promac LDM Series Excavator Mulcher

Product Overview

The LDM Series can be configured to run on hydraulic flows as low as 15 GPM @ 5000 psi and it will make quick work of brush and 6” and smaller diameter trees. This mulcher is available in 30” and 50” wide cut width and the drum can be equipped with your choice of three styles of cutter teeth to suit the working conditions. The mulcher is powered by a hydraulic variable torque bent axis piston motor with the Promac Automatic Torque Controller (ATC) for class leading productivity. Promac extensively utilizes high strength steel and wear resistant parts that are easily replaceable, ensuring your operation runs smoothly for years.

THE DRUM

The drum has the Promac “Chip Production Rotor” tooling system known in the industry as a “bite limiter”. This feature helps control discharge size while maintaining RPM. All holders and plates on the drum are manufactured from high strength steel for superior impact resistance and longevity.

THE TEETH

The drum accepts multiple tooling options to suit any budget, performance and ground condition, including: Proprietary rotatable knives for the best mulching performance in sand or soil, double carbides for longevity in rock and economically priced beaver teeth for good performance in most conditions.

THE FRAME

The frame is made of fully welded high strength steel and a boxed in design, which provides better rigidity than other open-end designs. This allows the LDM Series to be light weight and maintain great machine strength and stability when operating. The frame incorporates a large ‘pusher pad’ to permit the operator to ‘push’ on the heal of the mulcher without damaging the machine.

THE MOTOR

The hydraulic motor is directly coupled to the drum via an isolation coupler. This efficient system provides shock load protection for the drive motor. The motor also includes the Promac Automatic Torque Controller (ATC) as standard.

THE ADD-ONS

Optional Chain Bar: The optional chain bar was developed based on customer feedback and launched in early 2021. This is a simple and effective way to minimize the discharge of material out the rear of the mulcher while providing a sloped surface to guide the standing trees into the drum.

Custom Pin Mount: Promac can provide a custom pin mount to suit your carrier. Provide us the dimensions of your bucket connection and we will engineer a mount that perfectly fits your machine.

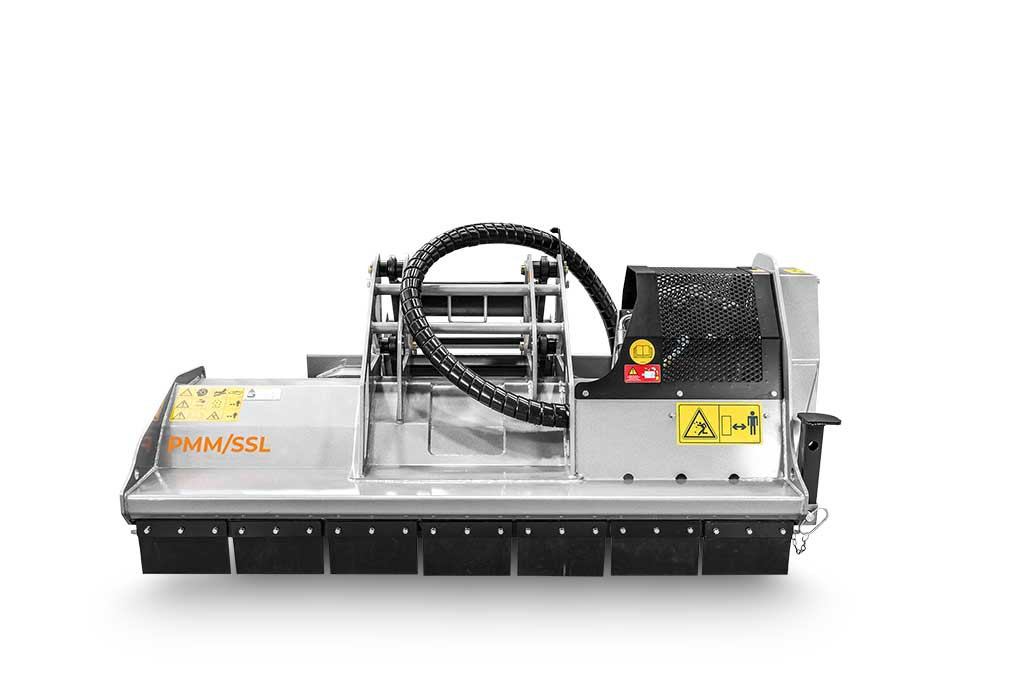

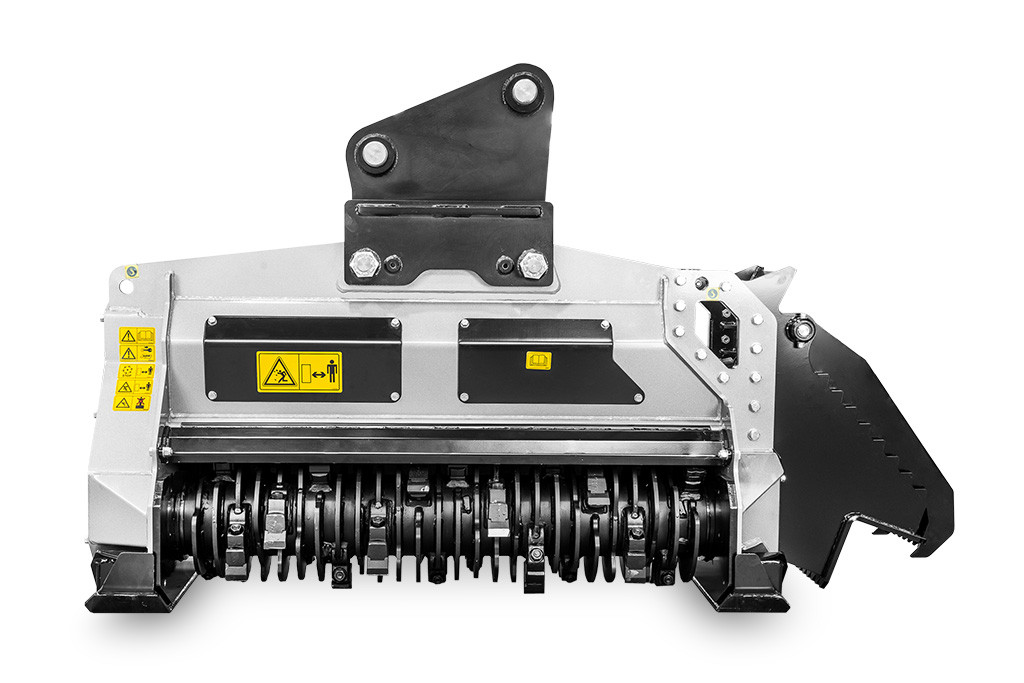

More products that you might be interested

More of Mulching Heads

Got a question?

We’re here to help you pick out the best tool that suits your unique needs.

CONTACT US

Call Van-Ed

Call Van-Ed