Hydraulic Hammers Equipment for Sale at Van-Ed Equipment

When it comes to demolition, quarrying, or road construction, the power and efficiency of hydraulic hammers can’t be understated. Many hydraulic hammer tools like concrete hammer, rock breakers and others are vital for breaking through concrete, rock, and other tough materials, ensuring swift and effective project execution. At Van-Ed Equipment, your project’s success is our mission. Serving the Lower Mainland, Fraser Valley, and BC, we provide reliable, high-quality hydraulic hammers for sale from trusted global brands. Equip your work with the power of Van-Ed for superior results.

New Hydraulic Hammers

Carrier: 0.8 to 2.5 tons

V Series V45

- Daily $250

- Weekly $500

Carrier: 1.5 to 4 tons

V Series V57

- Daily $275

- Weekly $525

Carrier: 3 to 6.5 tons

V Series V70

- Daily $300

- Weekly $650

Carrier: 4.5 to 8 tons

V Series V75

- Daily $325

- Weekly $700

Carrier: 4.5 to 8 tons

V Series V80

- Daily $425

- 425 $850

V Series V90

Carrier: 10 to 15 tons

V Series V105

- Daily $700

- Weekly $1,450

V Series V115

V Series V135E

V Series V135EX

V Series V145

V Series V155

V Series V165

V Series V175F

V Series V180F

Rammer 155E

Rammer 255E

Rammer 355E

Rammer 455E

Rammer 555E

Rammer 777E

Rammer 999E

Rammer 1322E

Rammer 1533E

Rammer 1655E

Rammer 2155E

Rammer 2166E

Rammer 2577E

Rammer 3288E

Rammer 4099E

Rammer 5011E

Rammer 9033E

Rammer 555E Heavy Duty Small

Rammer 777E Heavy Duty Small

Rammer 999E Heavy Duty Small

Rammer 555E Scaler

Rammer 777E Scaler

Rammer 999E Scaler

Rammer 2577 PRO

Rammer 3288 PRO

Rammer 4099 PRO

Rammer 5011 PRO

Rammer E01

Rammer E02

Rammer E04

Rammer R01P

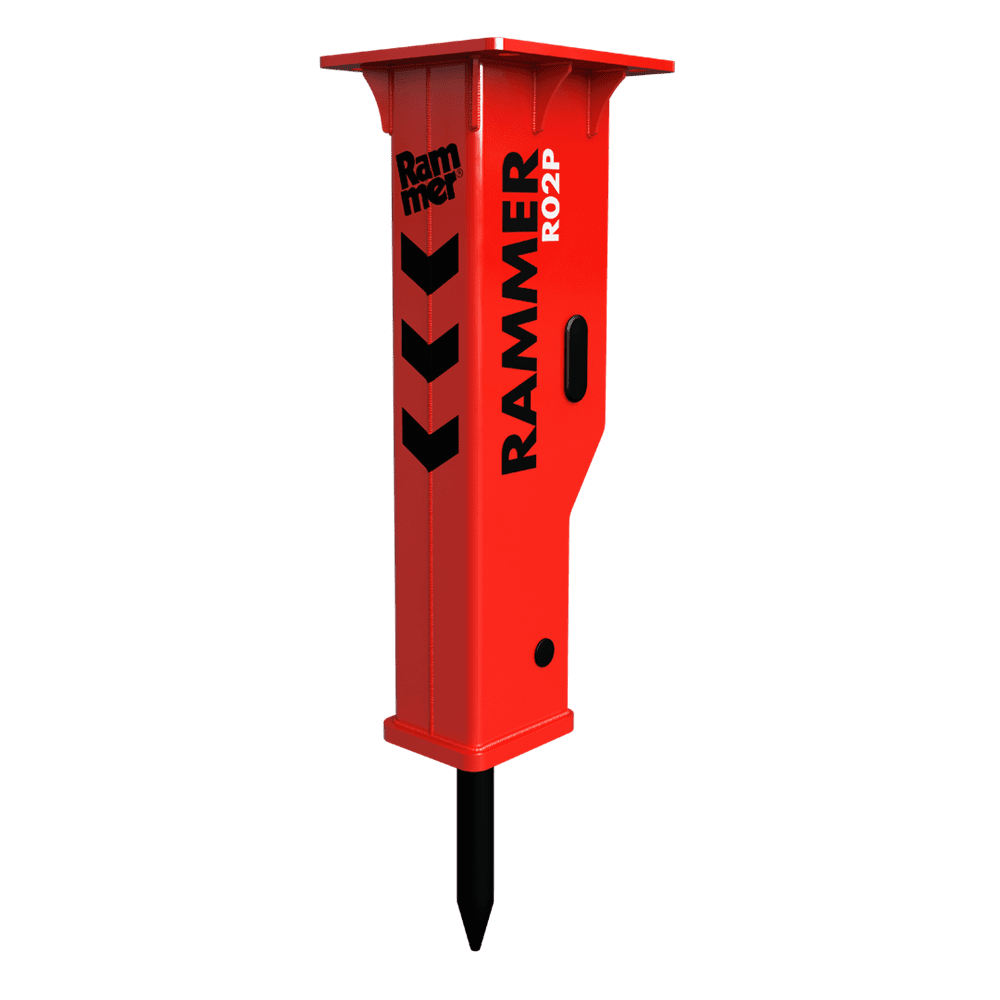

Rammer R02P

Rammer R03P

Rammer R04P

Rammer R05P

Rammer R07P

Rammer R10P

Rammer R12P

Rammer R16P

Rammer R18P

Rammer R25P

Rammer R35P

Rammer R45P

FAQ - Frequently Asked Questions

A hydraulic hammer is essential for efficiently breaking through hard materials like concrete and rock, making it ideal for construction, demolition, and mining applications. Its powerful, precise impact is unmatched for tasks requiring forceful, concentrated braking power. This tool is necessary for any job where traditional digging and drilling methods fall short.

A hydraulic hammer, rock breaker, and Hoeram are all tools designed to break hard materials but often differ in specialization. While ‘hydraulic hammer’ is a broad term for these attachments, ‘rock breaker’ is typically tailored for fracturing rock, and ‘Hoeram’ usually refers to a brand-specific hydraulic hammer for various demolition tasks.

A hydraulic breaker is versatile enough to serve as a rock hammer, adept at fracturing rock and concrete. Its robust design allows for efficient excavation in various environments. Whether chiselling through bedrock or demolishing old concrete, its performance remains consistent and reliable.

To maintain your hydraulic hammer or rock breaker, regularly check and grease moving parts, inspect hoses and seals for wear, and ensure tool bits are sharp and properly secured. Regular maintenance not only extends the lifespan but also ensures optimal performance. Always refer to the manufacturer’s guidelines for specific maintenance routines.

When operating a hydraulic breaker as a concrete hammer, focus on controlled, consistent impacts to crack and break the material. As a rock hammer, use more pointed chisels and vary the angle of attack to fracture the stone efficiently. In both applications, proper technique maximizes efficiency and extends the equipment’s lifespan.

Call Van-Ed

Call Van-Ed