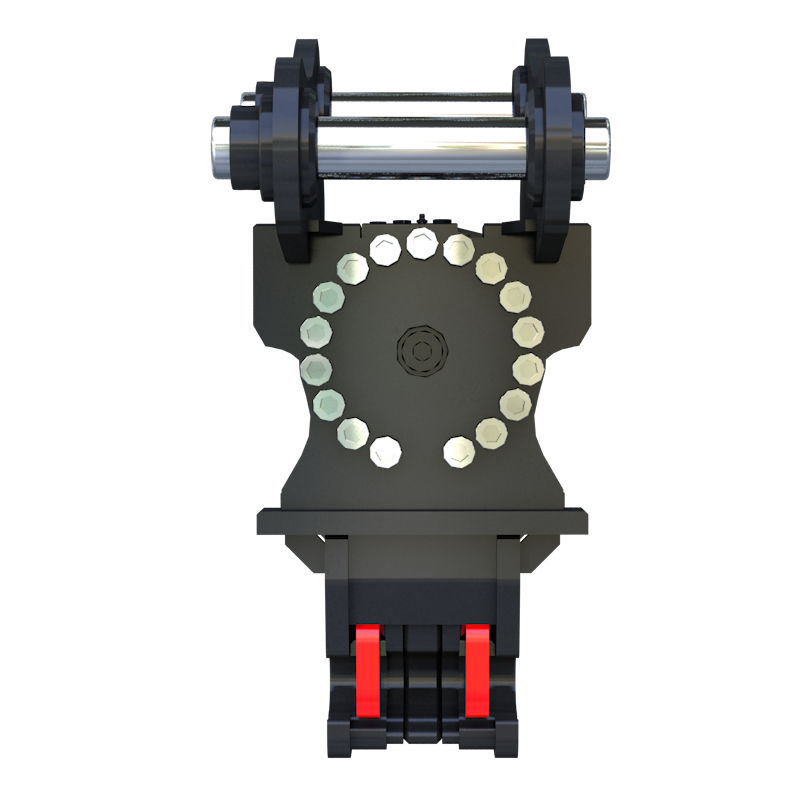

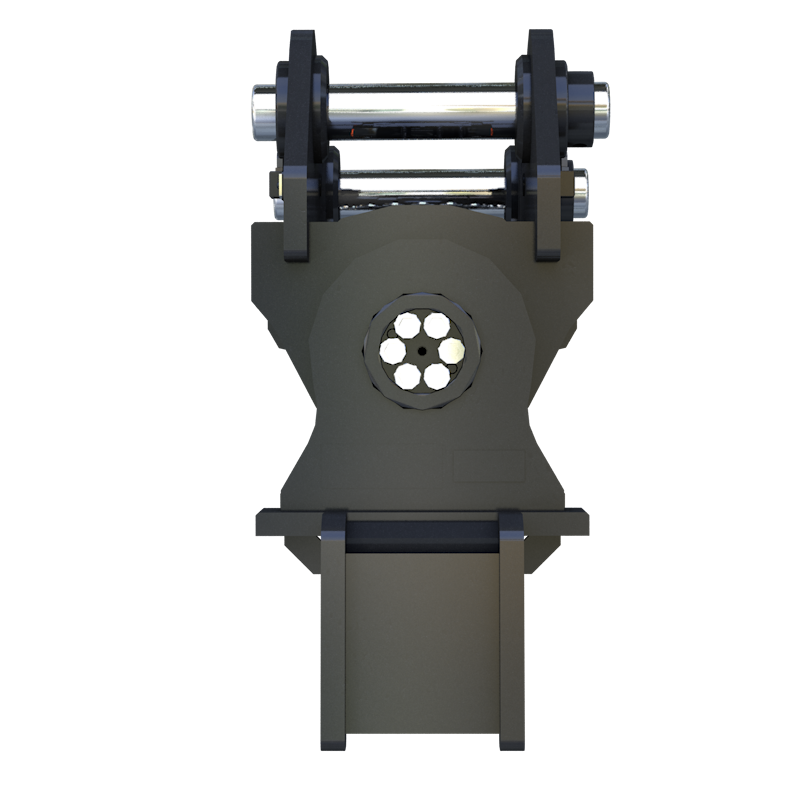

Tilt Couplers

AMI Powertilt Hydraulic Pin Grab Coupler

Tilt Couplers

AMI Powertilt Hydraulic Pin Grab Coupler

Product Overview

Connecting ease-of-use with jobsite safety and versatile operation is the AMI Axxis PowerTilt Hydraulic Pin Grab Coupler. With five integrated safety features, you receive all the safety benefits of our Hydraulic Pin Grab Coupler while gaining the added capability of 180 degree rotation on 25-70 series excavators and 120-degrees on 130-400 series excavators.

SIMPLIFIED COUPLER HOSE ROUTING

Compact and minimal hydraulic flow design protect the few hoses required for both tilt and coupling functions. Steel lines and internal routing eliminate exposed external hoses.

HARDENED STEEL SEALS AND BEARING SURFACES

Thrust and radial bearing surfaces for the PowerTilt Coupler are hardened steel on hardened steel, eliminating the need for bearing replacement. This also leads to longer coupler life and reduced cost of ownership.

UP TO 180° TILT RANGE

Instead of moving your entire machine, the PowerTilt allows bucket or attachment tilting up to 180°.

DUAL PROFILE PRECISION GRIP

A sharp talon and secondary socket profile allows continued handling of attachment during connecting and disconnecting.

2 STAGE IN-CAB CONTROLS

Easy to use and designed to prevent unintentional release, the in-cab controls require two unique actions to activate the hydraulic coupler’s unlocking sequence.

SAFE BUCKET POSITION REQUIRED

At full curl, the bucket is now safely resting in the coupler’s front clip without risk of falling off unexpectedly.

CONSTANT PRESSURE & LOAD HOLDING VALVE

Dedicated lines provide constant pressure directly to the coupler’s locking cylinder. Integrated into the locking cylinder is a load holding valve that keeps the attachment locked tightly to the coupler.

MECHANICAL SAFETY LOCK

Using a spring-loaded hydraulic cylinder, the safety naturally stays in the locked position and requires hydraulic pressure to deactivate.

More products that you might be interested

More of Tilt Couplers

Got a question?

We’re here to help you pick out the best tool that suits your unique needs.

CONTACT US

Call Van-Ed

Call Van-Ed